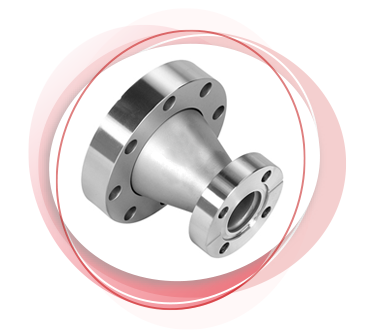

Katariya steel is one of the finest manufacturers, distributors, and exporters of Hastelloy C276 Flanges. Alloy C276 flanges have a high melting point of 1370 degrees Celsius. Alloy C276 flanges contain 16% maximum chromium, 57% maximum nickel, 16% maximum molybdenum and sulfur, manganese, silicon, cobalt, iron-carbon, and phosphorus in their composition. Alloy C276 Forged Flanges have outstanding corrosion resistance to a huge variety of chemical process environments. Hastelloy C276 flanges have excellent resistance to pitting and stress corrosion and are immune to wet chlorine gas, hypochlorite, and chlorine dioxide. C-276 alloy flanges have moderate to difficult machinability and good weldability. The alloy must be forged between 2250/1750 ºF (1230/955 ºC) after a quenching process at the forging temperature of about 30 minutes per inch of the billet.

Optimum corrosion resistance can be obtained by subsequent annealing of the forged parts. C276 (UNS N10276) is a wrought corrosion-immune alloy that resists the consistent development of grain boundary precipitates that degrade corrosion resistance. Some of the major applications of alloy C276 flanges are chemical processing, pulp, and paper production, recovery of sour natural gas, industrial and municipal waste treatment, and pollution control. Hastelloy C-276 flange product manufactured by Katariya steel has good oxidation & creep resilience and is available in a wide range for business purposes.

India

India Japan

Japan Russia

Russia United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Vietnam

Vietnam Oman

Oman Australia

Australia Qatar

Qatar Portugal

Portugal Mexico

Mexico Brazil

Brazil France

France South Africa

South Africa Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela