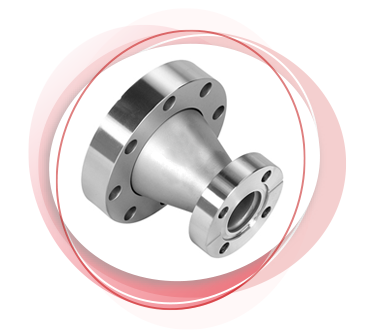

Alloy 600 Plate Flanges, 600 Inconel Flanges Manufacturer In India, Inconel Alloy 600 Class 600 LBS Flanges Manufacturer Supplier In Mumbai, 600 Inconel Reducing flanges, 600 Inconel Flanges Suppliers And Manufacturers, Dimensions Alloy 600 bs 10 Flanges, Alloy 600 wnrf Flanges Price List In India, Inconel 600 Flanges Manufacturer In India, ASME B16.5 Inconel Alloy 600 Threaded Flanges Supplier In Mumbai, 600 Inconel Flanges Catalogue, Inconel 2.4816 Flanges Supplier In India, Inconel 600 Socketweld Flanges Price List, Inconel 600 Ring Spacer Flanges Price, Inconel Alloy 600 SAE Flanges Supplier In India, Nickel Alloy 600 Flanges Price, Inconel 600 high hub blind flanges Manufacturer In India, Inconel 600 EN Flanges at Best Price, Nickel Alloy 600 Flanges Manufacturer In Mumbai, 600 Inconel Flanges Stockist In India, 600 Inconel EN-1092 Flanges, Alloy 600 nipoflange Price List Mumbai, Inconel 600 Loose Flanges, Inconel 600 din Flanges Specification, 600 Inconel Flanges Price, Inconel 600 Raised Face Flanges, 600 Inconel Flanges Manufacturers, Inconel 600 Flanges Supplier In Mumbai, Gr.600 Inconel Flanges Price List, Inconel Alloy 600 Pipe Flanges Stockist In Mumbai, Inconel 600 Flanges Supplier In India, Inconel Alloy 600 Flat Face Blind Flanges Price List In India, Inconel® Alloy 600 Flanges at Best Price, Inconel 600 Flanges Manufacturer In Mumbai India, Inconel 600 welding neck flanges Exporter, 900 LBS Alloy 600 Flanges Exporters In Mumbai, Inconel 600 Flanges Suppliers In India, Inconel® Alloy 600 Flanges Price List, ASME B16.47 600 Inconel Flanges Manufacturer in Mumbai, Inconel 600 Flanges Manufacturer In Mumbai, Inconel Alloy 600 Screwed Flanges, 600 Inconel Flat Flanges Supplier In India, Inconel Alloy 600 Flanges Stockholder, Inconel 600 Rtj Flanges, 600 Inconel Forged Flange Manufacturer In India, 600 Inconel Alloy Flanges Dimensions, Inconel UNS N06600 Flanges, Inconel Alloy 600 Industrial Weld Neck Flanges, Inconel 600 Screwed-Threaded Flanges Dealer In Mumbai, Inconel 600 BSP Thread Flanges, Inconel Alloy 600 Flanges Manufacturer In India, Alloy 600 NPT Thread Flanges Price List India, BS4504 Alloy 600 Flanges Stocks, Price Of Flanges Inconel 600 Inconel Flanges Supplier In Mumbai, Alloy 600 orifice flanges Wholesale Price, Inconel 600 Flanges Supplier In Maharashtra, Inconel Alloy 600 Flanges Supplier In India, 600 Inconel Flanges Dealer, Alloy 600 Flanges Manufacturer In Mumbai India, Inconel 600 Forged Elbow Supplier In Mumbai, ANSI B16.48 600 Inconel raised face flanges Price List, Alloy 600 Square Flanges In India, Inconel® Alloy 600 Flanges Suppliers In Chennai.

India

India Japan

Japan Russia

Russia United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Vietnam

Vietnam Oman

Oman Australia

Australia Qatar

Qatar Portugal

Portugal Mexico

Mexico Brazil

Brazil France

France South Africa

South Africa Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela