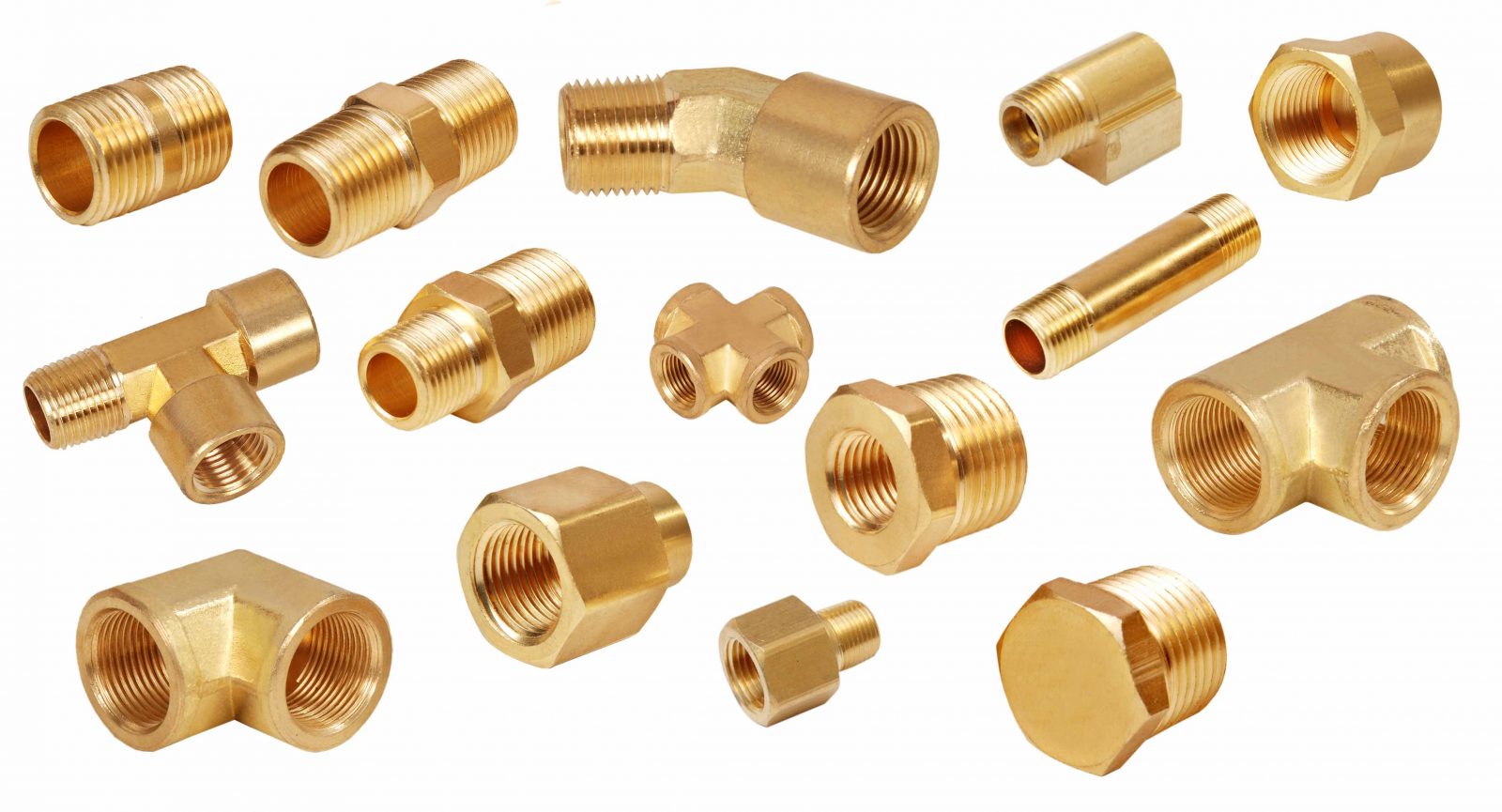

In an industrial market that has been swooned over by the use of stainless steel components, brass alloy still plays a major role. This alloy was discovered centuries ago and has been used ever since for a multitude of applications. Brass is an alloy made by mixing zinc and copper in varying proportions. One of its major applications is plumbing devices. Components made out of brass are highly reliable to build a plumbing system. Its variance of application ranges from small household plumbing applications to large-scale industrial plumbing fittings.

5 benefits to choose brass pipe fittings for your next project:

-

Versatility:

ASTM B62 Brass Pipe Fittings are used for numerous purposes ranging from industrial fitting applications to small household plumbing applications. Hence, brass fittings are available in varying sizes and shapes. Brass fittings are known to permit the alteration of pipe sizes. For a project or product that demands precise fittings with strict specifications, brass is the best choice. Brass pipes are the best and most efficient choice for making water transport and delivery pipelines in households. One can also customize the finishing of the alloy to enhance the appearance and beautify the look of the fitting.

-

Highly Durable:

Brass alloys are extremely strong and have a very long service life. This makes brass fasteners highly durable. Brass fasteners are capable of maintaining their shape and preventing the pipe from damage. They do not succumb and crack under pressure.

-

Heat tolerance:

When a fitting has to be chosen for a pipeline distributing hot water, brass is the best choice of metal. Brass has got great heat conductivity and hence improves the efficiency of hot water pipelines. If a serious fire had to break out, the only material that would potentially survive is brass. Thus, proving that brass fittings have great heat tolerance and can withstand extreme temperatures.

-

Resists Corrosive media:

Brass is the #1 material when it comes to anti-corrosive properties. It resists serious wear and tears caused by corrosive media. For fittings that have to be installed in areas that are prone to corrosion, the brass should be the best and only choice. It is guaranteed via tests that even the most corrosive water bodies cannot affect brass and brass components.

-

Extremely malleable and ductile:

When it comes to choosing a metal alloy that can be beaten, bent, elongated, flattened, and shaped, Brass is the best option. It is way more malleable than several other metal alloys in the market. It has great workability which reduces the requirement for labor. Even after being elongated and beaten into numerous shapes and sizes, brass does not lose its durability and strength.