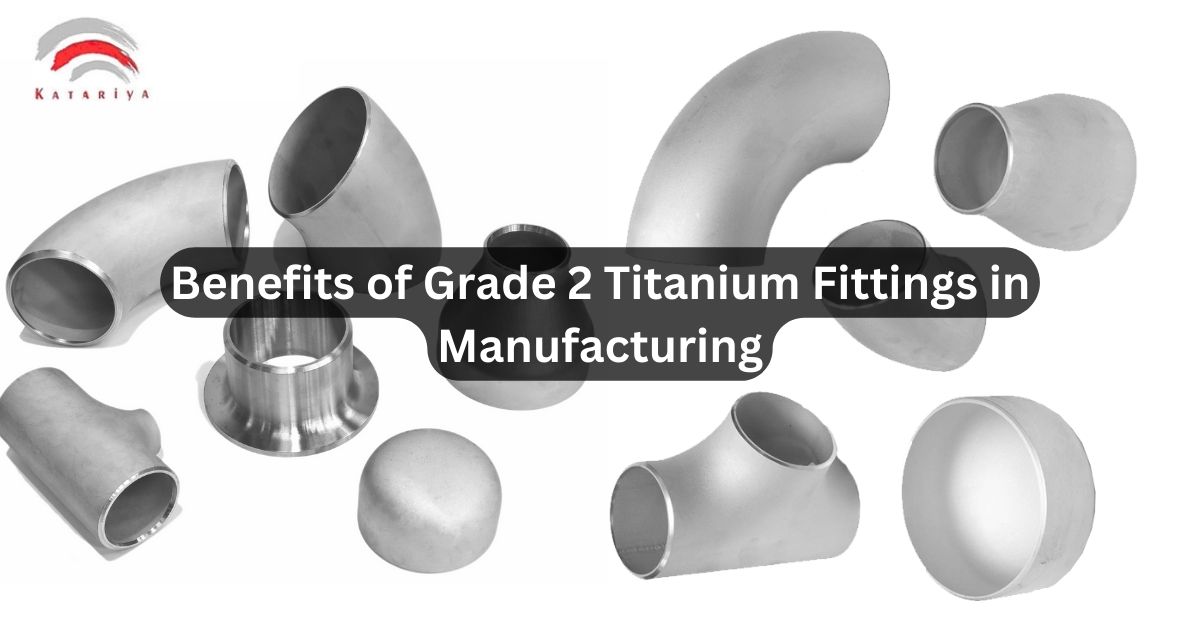

Grade 2 titanium is a highly versatile and durable material widely used in various industrial applications. One area where it can make a significant difference is in manufacturing and fabrication processes.

In this article, we will explore how Grade 2 titanium fittings can improve the efficiency of manufacturing and fabrication processes.

Improved Strength and Durability

Grade 2 titanium has a high strength-to-weight ratio and excellent corrosion resistance, making it an ideal material for manufacturing and fabrication. Its strength and durability mean it can withstand harsh environmental conditions and heavy loads without degrading or breaking. This property makes Grade 2 Titanium Fittings highly reliable and suitable for long-term use in various industrial applications.

Reduced Maintenance and Downtime

Grade 2 titanium fittings in manufacturing and fabrication processes can lead to reduced maintenance and downtime. Due to high strength and corrosion resistance, they are less likely to rust, wear, or break down over time. This property requires less maintenance and is less prone to failure, leading to reduced downtime and increased productivity.

Lightweight and Easy to Handle

Another benefit of Grade 2 titanium fittings is their lightweight nature. Compared to other metals such as steel and copper, Grade 2 titanium metal is light, making it easy to handle and move around during manufacturing and fabrication. This property reduces the risk of worker fatigue and injuries, leading to increased safety and efficiency.

Resistance to Corrosion and High Temperatures

Grade 2 titanium has excellent resistance to corrosion and high temperatures. This property makes it suitable for harsh environments and high-temperature applications, such as chemical processing and aerospace manufacturing. Grade 2 titanium fittings in these applications ensure long-lasting performance and reliable operation.

Compatibility with Various Chemicals

Grade 2 titanium is compatible with various chemicals, making it ideal for chemical processing applications. It is highly resistant to many acids and alkalis, making it suitable for use in the manufacture of chemical products. This property ensures that Grade 2 Titanium Fittings will not react with the chemicals they come into contact with, ensuring long-lasting and reliable performance.

In conclusion, Grade 2 titanium fittings can significantly improve the efficiency of manufacturing and fabrication processes. They offer improved strength and durability, reduced maintenance and downtime, lightweight and easy handling, resistance to corrosion and high temperatures, and compatibility with various chemicals. By using Grade 2 titanium fittings, manufacturers and fabricators can improve the quality and reliability of their products while increasing productivity and reducing costs.